|

| October 23, 2018 | Volume 14 Issue 40 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

GE designing engine for world's first supersonic business jet

On Oct. 15, GE Aviation announced that it has completed the initial design of the first supersonic engine purpose-built for business jets. The new engine class, which will be featured on the Aerion AS2 plane, will be called the GE Affinity turbofan. Aerion Corporation (Reno, NV) plans to fly the AS2 12-passenger jet in 2023, with certification in 2025.

Other development partners in the venture include Lockheed Martin and Honeywell.

The announcement by GE "is a huge step forward in realizing this airplane," says David Richardson, Lockheed Martin Skunk Works' director of air vehicle design. "For us to design a clean-sheet airplane at Skunkworks, we always start with an engine. Without an engine, you don't have an airplane. It is the enabler, really, for this whole enterprise."

This AS2 aims to save travelers as much as three hours across the Atlantic and five hours across the Pacific. It will be as much as 60 percent faster than today's civil jets. The jet will also attempt to redefine the passenger experience, providing a new level of luxurious and connected flight at 1,000 mph.

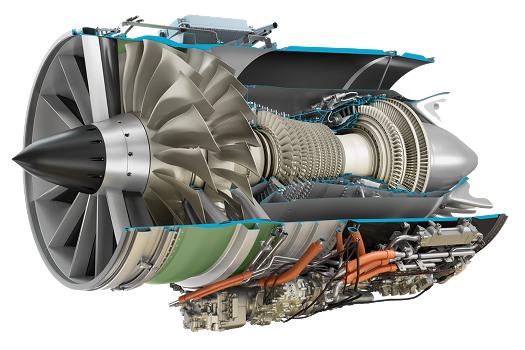

The Affinity is a new class of medium bypass ratio engines from GE that provides exceptional and balanced performance across supersonic and subsonic flights. GE says the engine "integrates a unique blend of proven military supersonic experience, commercial reliability, and the most advanced business jet engine technologies."

GE's Affinity is a twin-shaft, twin-fan turbofan controlled by a next-generation Full Authority Digital Engine Control (FADEC) for enhanced dispatch reliability and onboard diagnostics. It is purposefully designed to enable efficient supersonic flight over water and efficient subsonic flight over land -- without requiring modifications to existing compliance regulations. The engine is designed to meet stringent Stage 5 subsonic noise requirements and beat current emissions standards.

GE's Affinity engine features:

- Efficient performance throughout the full flight envelope with a high-altitude service ceiling of 60,000 ft.

- An advanced twin-fan with the highest bypass ratio of any supersonic engine.

- A special, non-augmented supersonic exhaust system.

- A proven engine core adapted from GE's commercial airline portfolio with billions of successful and reliable hours of operational service.

- A durable combustor with advanced coatings for sustained high-speed operation.

- Advanced acoustic technology designed to meet or exceed regulatory requirements.

- GE's additive design amd manufacturing technologies to optimize weight and performance.

"In the last 50 years, business aircraft speeds have increased by less than 10 percent," says Brad Mottier, GE vice president and general manager for Business and General Aviation & Integrated Services. "Instead of going faster, cabins have increased in size and become more comfortable -- and range has become longer. With large, comfortable-cabin, long-range aircraft in the marketplace, the next step is speed ... made possible with GE's Affinity."

After two years of a preliminary study, GE Aviation and Aerion launched a formal process in May 2017 to define and evaluate a final engine configuration for the AS2 supersonic business jet. A GE Project team, supported by a dedicated engineering team, continue to work with Aerion in a formal and gated process. The next design review is targeted for 2020, signaling the beginning of detailed design and test article production.

"Our mission is to enhance global mobility with supersonic speed, starting with business aviation, and following with successively faster and larger designs for business and commercial aviation," says Aerion CEO Tom Vice. "GE Aviation is making this new efficient, sustainable supersonic era possible through its pioneering work on the Affinity engine."

Honeywell is uniquely positioned to provide the avionics for the world's first supersonic business jet. Honeywell Primus Epic avionics are currently standard equipment on leading business and regional jet OEM platforms and in service on nearly 5,000 aircraft in 20 different models. Primus Epic has accrued nearly 30+ million total flight hours.

Similarly, Honeywell mission processors, displays, sensors, radio altimeters, radar, and flight control systems have been enabling thousands of supersonic military jets for decades. Most supersonic aircraft in the free world use various Honeywell avionics systems and components. This unique combination of business jet and supersonic experience will enable Honeywell to offer an innovative supersonic business jet cockpit for the AS2.

Full-scale engineering mockup for the Aerion AS2's cockpit and cabin design.

Sources: Aerion Corporation, GE

Published October 2018

Rate this article

View our terms of use and privacy policy